Why 3D Printing Is Revolutionising the Work of Today’s Model Builders

Architects have always relied on physical miniatures to communicate ideas, but the process has changed dramatically as digital tools evolve. Today, the work of a model builder blends artistic skill with advanced fabrication technology, creating highly detailed representations at a pace that was unthinkable in the past. This shift has made physical design models more accessible, repeatable, and visually impressive.

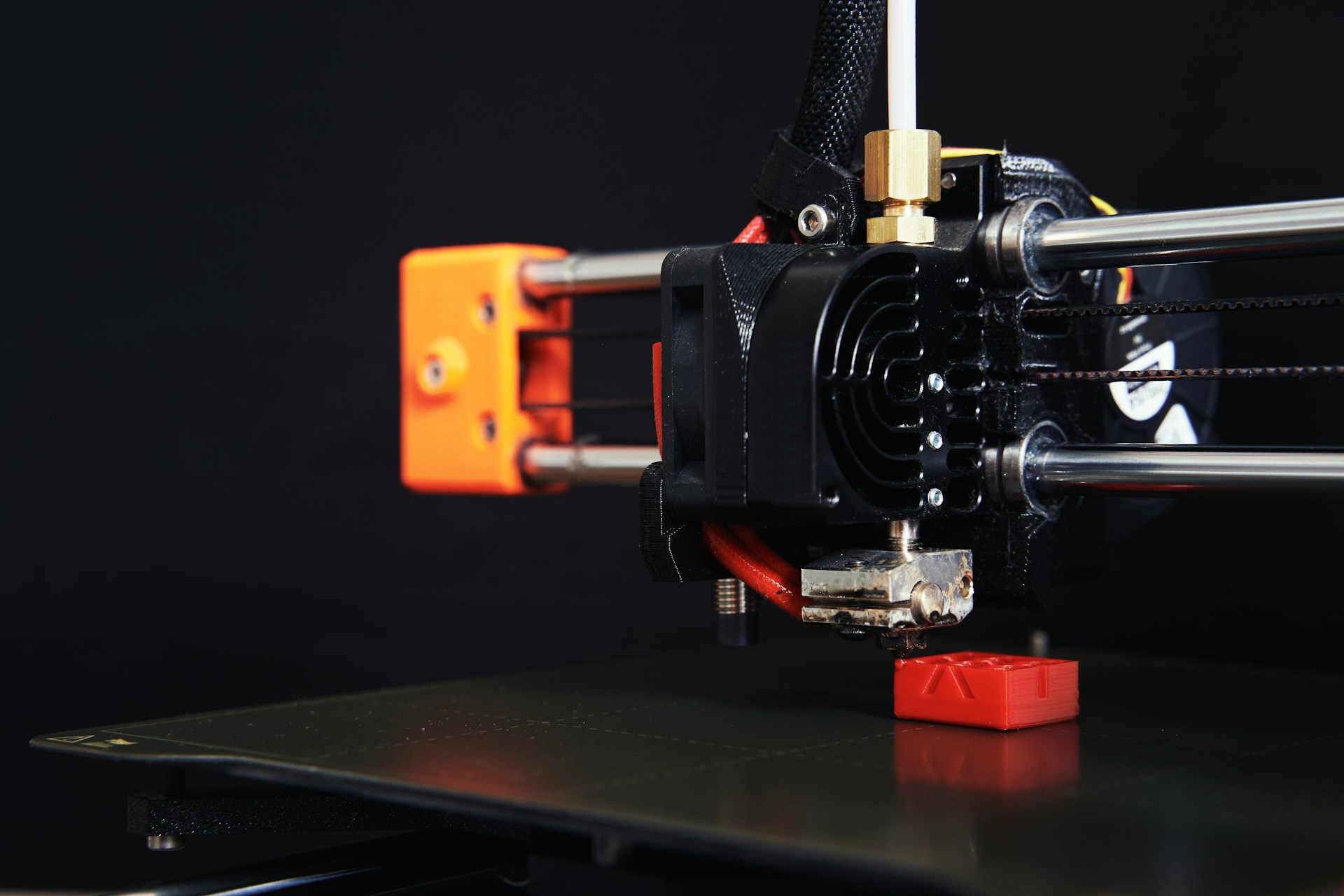

While manual crafting once dominated the field, many studios now integrate 3d printing into their creative workflow. The combination of precision machinery and digital design software allows teams to test concepts early and refine them quickly. As a result, even complex forms can be explored with confidence before heading into costly construction phases.

The demand for a realistic architectural model continues to grow as clients and stakeholders expect clearer visual communication. With modern fabrication tools, teams can now deliver intricate structures and polished presentations that elevate understanding and reduce misinterpretation — something that benefits both project owners and design professionals.

New Levels of Detail Through Additive Fabrication

Accuracy is one of the greatest advantages of additive manufacturing, especially when compared to traditional manual shaping. Layer-by-layer construction captures tiny features that once took hours to sculpt, carve, or cut. Everything from railings and window mullions to textured surfaces comes out with clean uniformity.

In many studios, digital files are divided into smaller components before printing, ensuring each part retains crisp detail. Once assembled, the result feels far more sophisticated than older foamboard or cardboard representations. This high fidelity helps clients imagine depth, light flow, and material transitions in a way flat drawings cannot replicate.

These improvements also help architects evaluate their own design decisions. With a highly accurate miniature in hand, errors in scale, balance, or proportion become easier to detect and correct.

Workflow: How Physical Models Are Produced With Modern Tools

Different firms follow different approaches, but the core steps typically remain similar. A streamlined workflow might look like this:

-

Import digital drawings or sketches into modelling software.

-

Optimise the geometry to ensure smooth fabrication.

-

Print the building sections, façade elements, and landscape details.

-

Clean, cure, and sand each component.

-

Assemble pieces with adhesive, paint, and additional supportive detailing.

-

Add finishing touches such as trees, lighting, or street elements.

This structured process shortens production time dramatically, allowing multiple iterations if the design evolves.

Why Architects Value Physical Models in Presentations

Even with advanced rendering tools available, physical miniatures continue to impress audiences. When stakeholders can physically touch and explore a shape, the conversation becomes more engaging and productive. This is especially helpful during early decision-making phases, where misunderstandings can lead to unnecessary delays.

A solid presentation model also improves internal collaboration. Engineers, planners, and consultants often interpret three-dimensional objects more easily than two-dimensional drawings, especially when reviewing massing, circulation, or structural challenges. Being able to walk around a miniature and discuss modifications fosters stronger communication across disciplines.

Teams also benefit from easy duplication. Once a digital version exists, additional copies can be produced with minimal effort for exhibitions, investor pitches, or public consultations.

Material Efficiency and Environmental Advantages

One major benefit of additive fabrication is its ability to reduce waste. Traditional methods rely on cutting and trimming materials, producing offcuts that often cannot be reused. By contrast, additive processes build only the required shapes, meaning far fewer scraps.

Some firms now incorporate biodegradable or recycled filaments to lower environmental impact. Lightweight plastics, plant-based materials, and resin blends are becoming common, especially for large projects that require numerous components. These sustainable choices make physical modelling a more eco-friendly part of the design lifecycle.

How Modern Fabrication Enhances Creativity

The precision of additive technology encourages experimentation. Designers are no longer limited by what can be cut, sculpted, or glued by hand. Instead, they can try unconventional geometries, complex lattice structures, or free-flowing curves that would previously have been too time-consuming to build.

Many architectural teams now explore alternative façade designs, shading devices, and structural variations by printing several versions at once. This rapid exploration helps refine aesthetics and solve technical challenges early, ultimately leading to better buildings.

As complexity becomes easier to reproduce, creativity expands. It empowers teams to challenge convention, test bold ideas, and present clients with engaging visual options.

The Role of Craftsmanship in a Digitally Driven Process

While machines handle the precision, human skill remains essential. Assembly, painting, landscaping, and presentation still rely heavily on craftsmanship. A well-trained eye can spot misalignments, adjust finishes, and create realistic textures that elevate a basic print into an expressive miniature.

-

Hand-applied paint enhances depth and realism

-

Custom landscaping adds context to the design

-

Fine-tuned adjustments ensure clean joints and edges

-

Surface finishing can mimic concrete, timber, stone, or steel

Digital tools may speed up production, but manual refinement provides personality and artistic quality.

Future Trends in Architectural Miniatures

The evolution of fabrication tools shows no signs of slowing. Colour-integrated printing is becoming more mainstream, multi-material printers are increasingly accessible, and machines capable of producing both rigid and flexible components in one pass are already entering professional studios.

Looking ahead, we may see hybrid methods where printed pieces combine with CNC-cut materials, laser-etched glass, or smart lighting components. These techniques will enhance realism and allow architectural teams to create interactive, highly immersive miniature environments.

The intersection of technology and craftsmanship continues to redefine what physical models can achieve. With tools improving rapidly, designers are gaining the ability to portray their visions with astonishing clarity and nuance. And as clients continue to value tangible, visually rich representations, these models will remain an essential part of the architectural design journey.